ADVANCED AI-EMPOWERED PLATFORM

QMULUS delivers secure, actionable operational data, driving digital efficiency for heat treaters beyond SCADA's capabilities.

WHY CHOOSE QMULUS?

Discover the countless advantages that our technology can provide for your business

Get full visibility

QMULUS provides real-time access to critical information about all machinery, non-machinery, and production data, allowing for quick and insightful decision-making.

Integrate

equipment seamlessly

QMULUS enables seamless connection and communication with NITREX brand, third-party, and custom controllers, providing a comprehensive overview of your processes and optimizing recipe control.

Enhance decision-making

QMULUS provides data-driven insights into processes and equipment, enabling informed decision-making to drive production improvements and optimization opportunities.

Increase

efficiency & save costs

QMULUS optimizes your workflow to reduce equipment idleness, avert bottlenecks, eliminate wasted resources, and streamline processes to save on operational costs.

Run greener operations by tracking “green KPIs”

QMULUS promotes environmental accountability by improving production efficiencies and reducing waste, helping you build a greener future while maintaining profitability.

Differentiate

from competition

QMULUS will set you apart from the competition with reliable quality, repeatable results and cost advantages. It makes you more attractive to new customers by offering a forward-looking and transparent solution with the possibility to involve the clients themselves.

Get full visibility

QMULUS provides real-time access to critical information about all machinery, non-machinery, and production data, allowing for quick and insightful decision-making.

Integrate

equipment seamlessly

QMULUS enables seamless connection and communication with NITREX brand, third-party, and custom controllers, providing a comprehensive overview of your processes and optimizing recipe control.

Enhance decision-making

QMULUS provides data-driven insights into processes and equipment, enabling informed decision-making to drive production improvements and optimization opportunities.

Increase

efficiency & save costs

QMULUS optimizes your workflow to reduce equipment idleness, avert bottlenecks, eliminate wasted resources, and streamline processes to save on operational costs.

Run greener operations by tracking “green KPIs”

QMULUS promotes environmental accountability by improving production efficiencies and reducing waste, helping you build a greener future while maintaining profitability.

Differentiate

from competition

QMULUS will set you apart from the competition with reliable quality, repeatable results and cost advantages. It makes you more attractive to new customers by offering a forward-looking and transparent solution with the possibility to involve the clients themselves.

DISCOVER OUR SOLUTIONS

essential & analytics

add ons

standalone

Qmulus Essential & Analytics

Better visibility of your operations with all real time equipment related information at your fingertips, in a single place, everywhere you go.

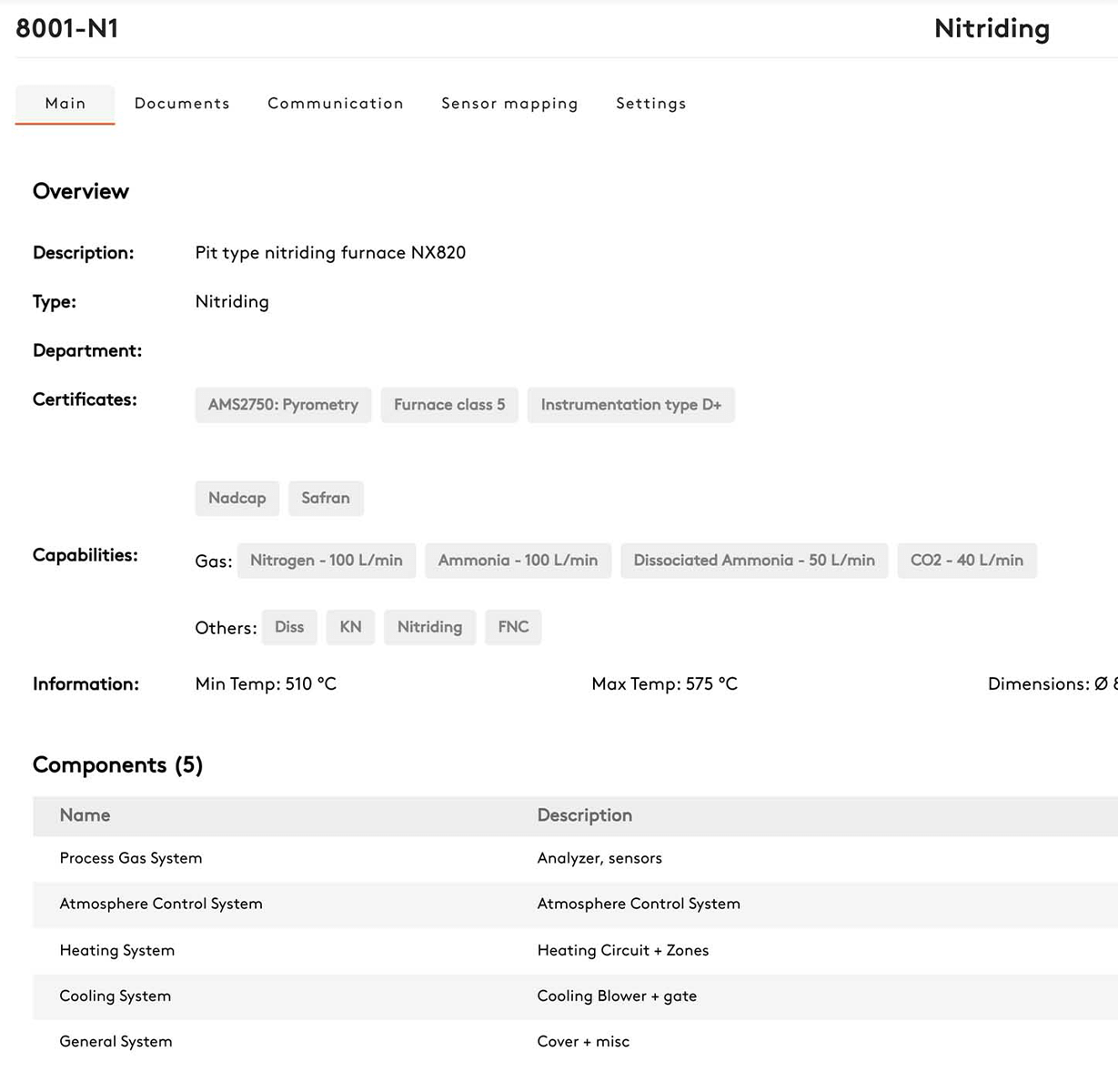

Asset management

Gain a comprehensive overview of all assets across your entire company. Centrally store all asset-related files and documents for easy accessibility at all times.

Qmulus Essential & Analytics

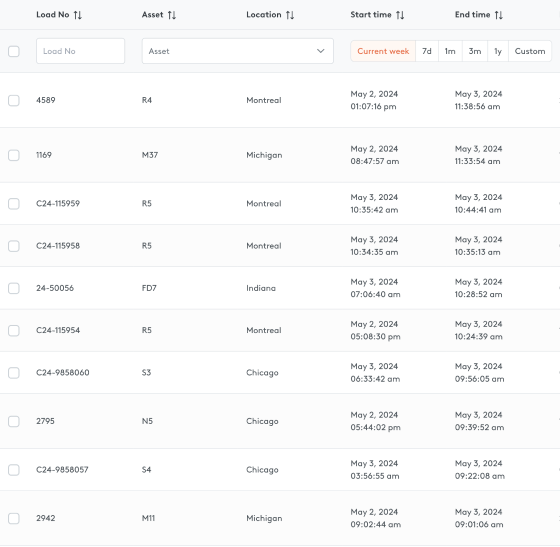

Production logs

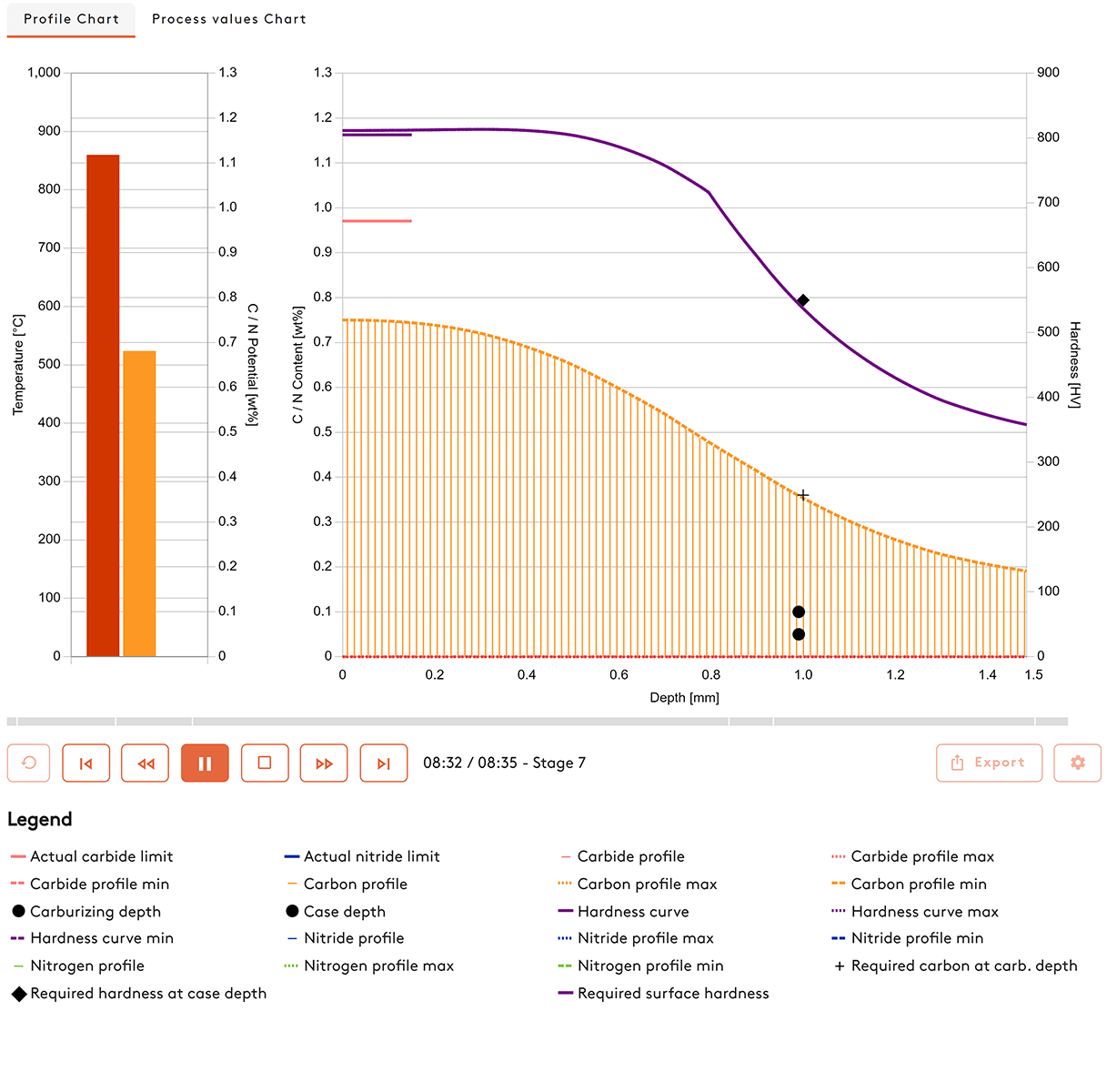

Access all loads and processes available in QMULUS, from detailed views and ratings of single processes to multiple process comparisons in a single dialog with Chart Recorder.

Qmulus Essential & Analytics

Chart recorder

Visualize process data including load-specific information such as alarms, recipe steps, and more. Feature accessible through multiple apps in QMULUS.

Qmulus Essential & Analytics

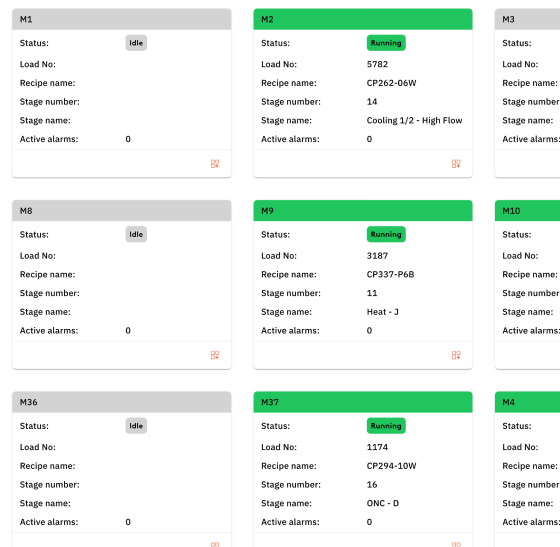

QMULUS Live app

View the current furnace status, running recipe, active alarms, and job chart.

Qmulus Essential & Analytics

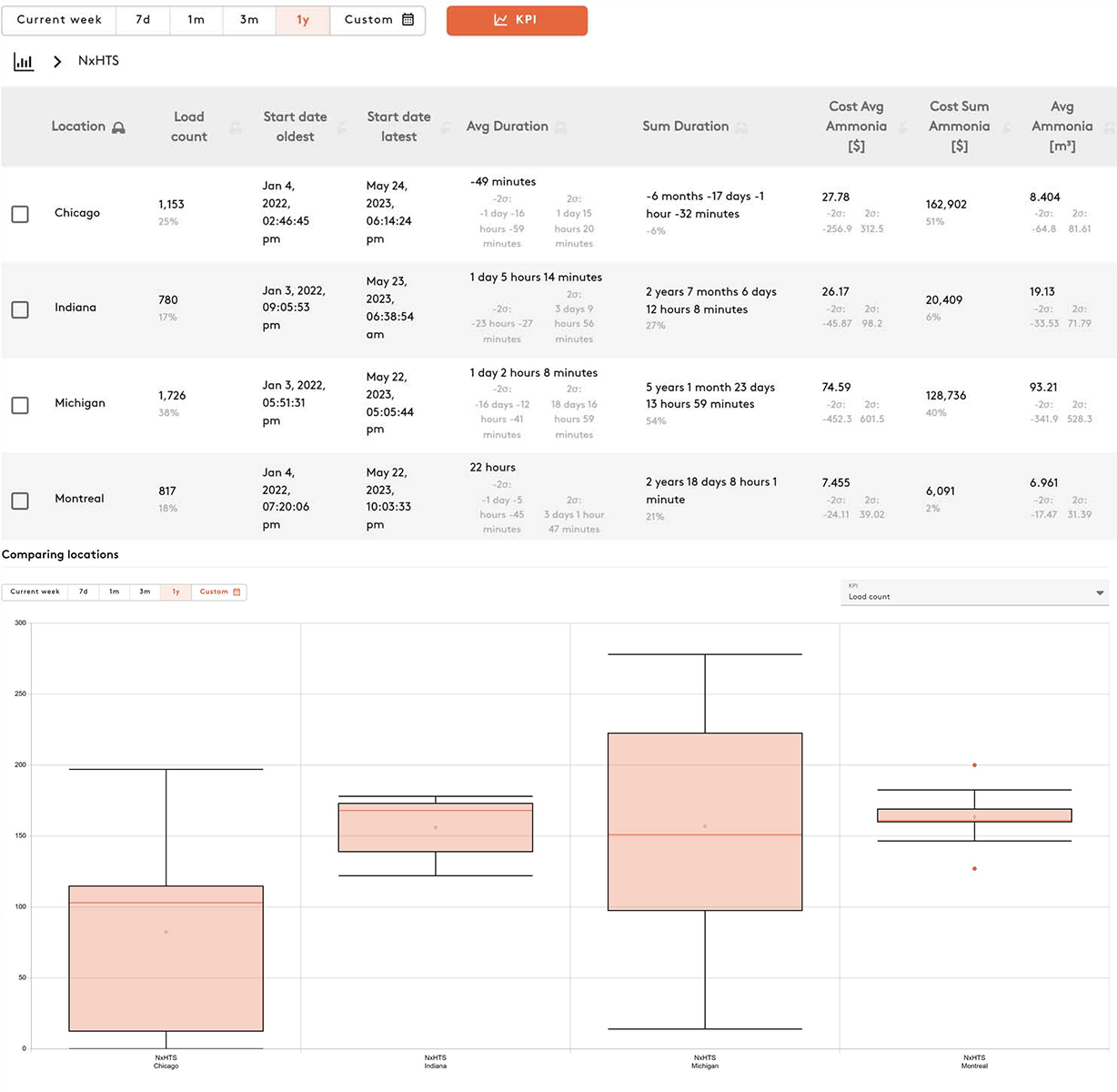

Performance dashboard

Improve productivity through better insights into consumables and other plant and asset consumption performance indicators.

Qmulus Essential & Analytics

QMULUS Analytics

Gain valuable statistics and KPIs for specific frames, entire divisions, locations, selected assets, or individual recipes with detailed analytics, and eliminate issues that have the most impact.

- Production statistics

- Outage statistics

- Alarm statistics

- History & trends

Qmulus add ons

Elevate your QMULUS experience with these add-on modules, including mobile accessibility, recipe design, process modeling, quality auditing, and analytics for detailed statistics, and more.

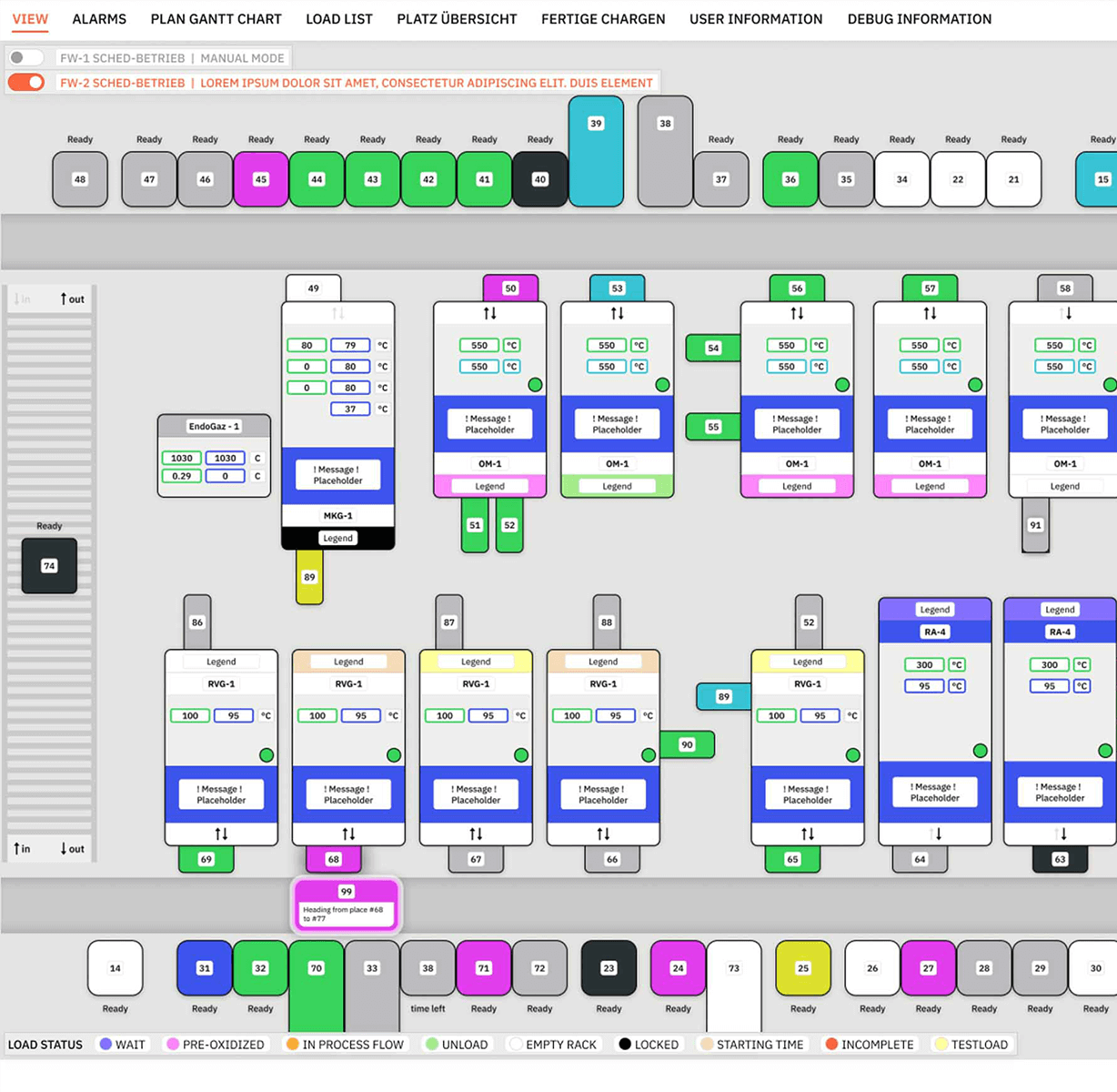

QMULUS Operations & performance

Interact with your shop from anywhere, acknowledging alarms and creating and managing recipes easily.

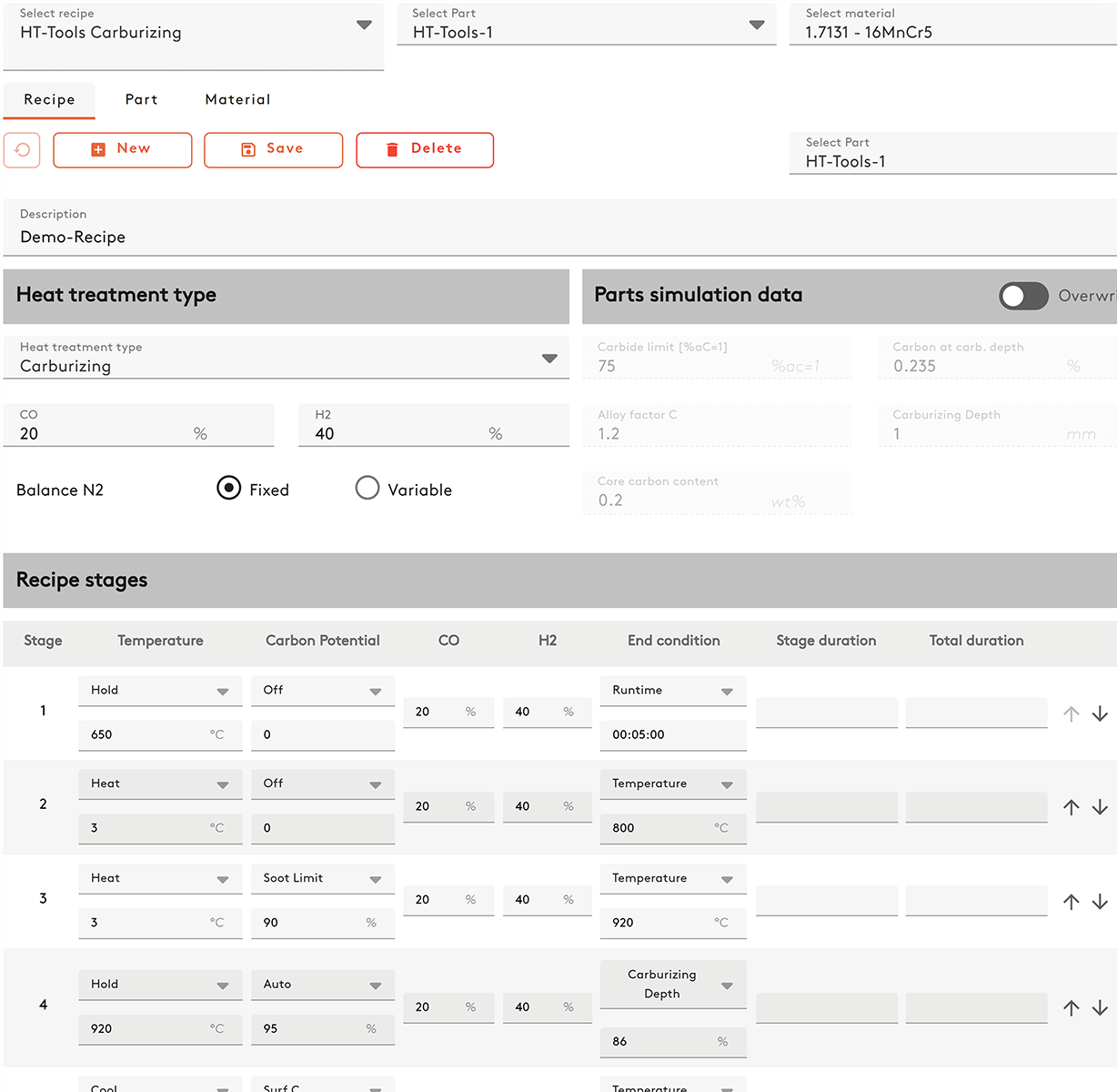

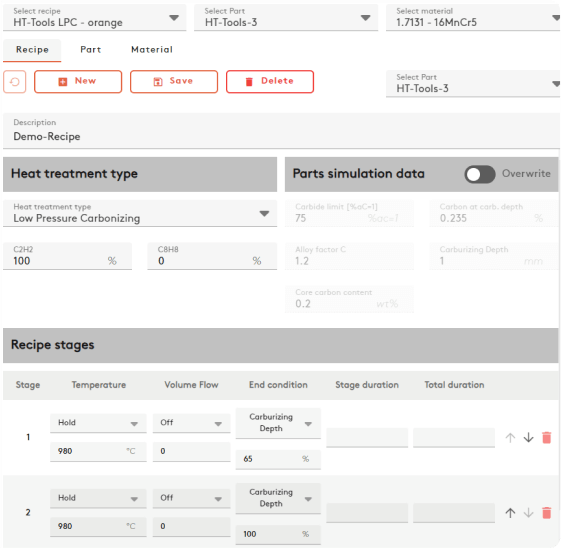

- Recipe builder

- Operations dashboard

- Remote control

- Furnace views

Qmulus add ons

QMULUS Operations & performance

Improve quality operations with our custom part/material databases: browse and create recipes, assign loads to connected equipment, and optimize production processes.

- Shop layout

- Materials database

- Load planning

- Parts database

- Serial number tracking (Feature Coming Soon)

Qmulus add ons

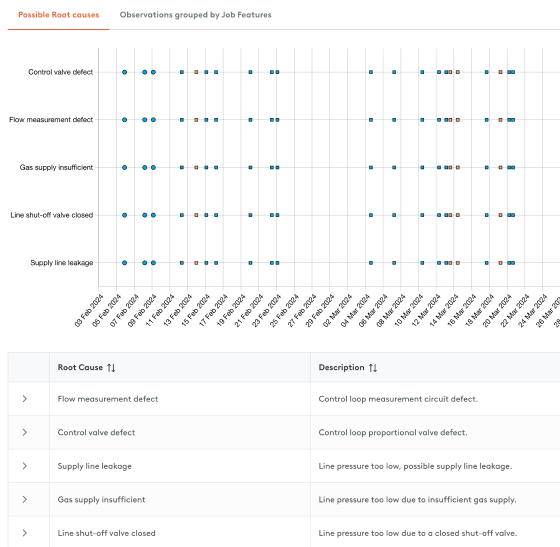

QMULUS AI

Create model processes as benchmarks, and benefit from documented root cause analysis to detect equipment and process anomalies for improved operations.

- Model process

- Anomaly detection

- Root cause analysis

Qmulus add ons

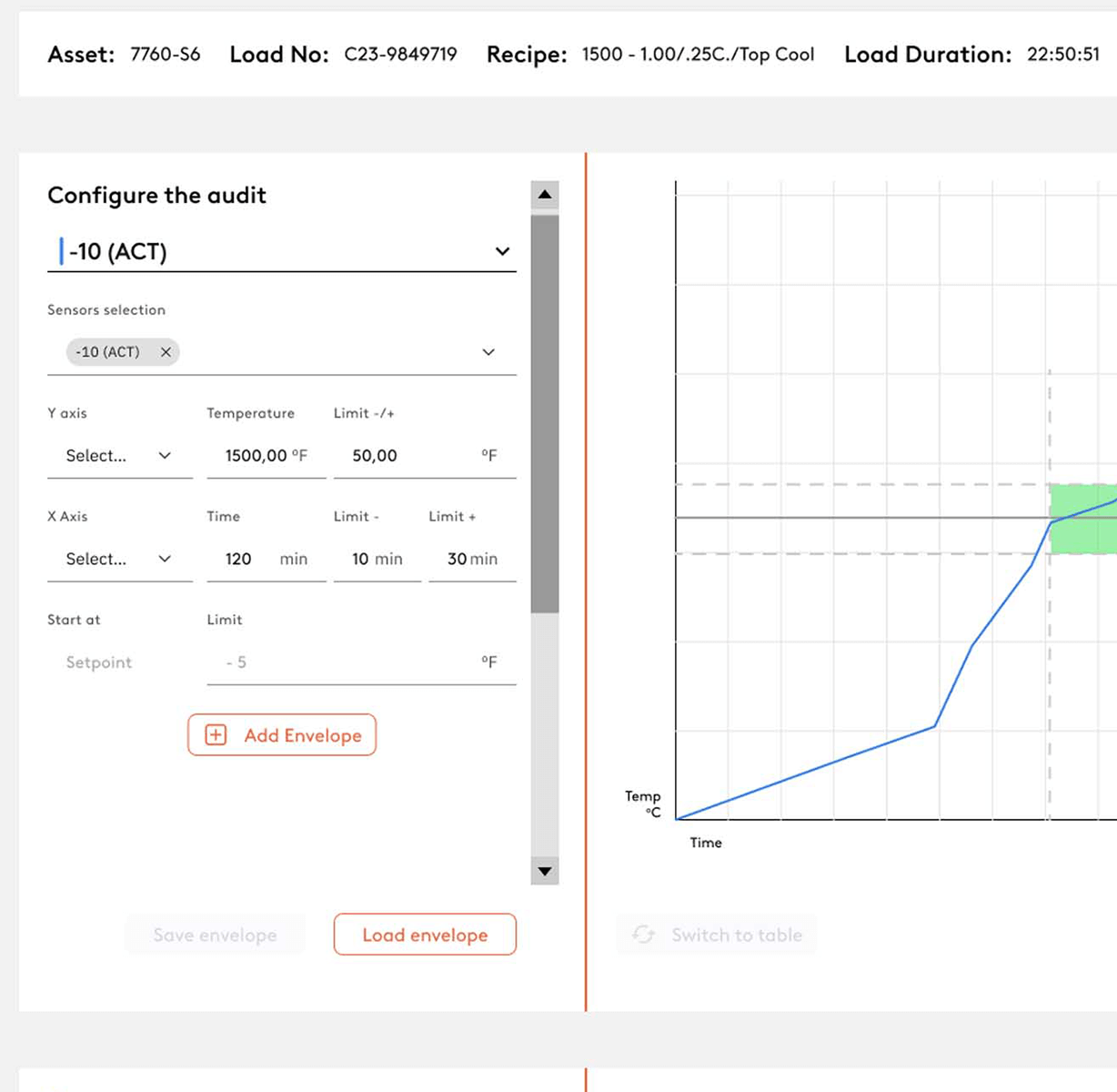

QMULUS Audit

Apply customized audits on your treatments, connect your laboratory, and document lab results for enhanced quality control.

- Lab reports

- Quality audit tool

- Automated audits (Feature Coming Soon)

Qmulus add ons

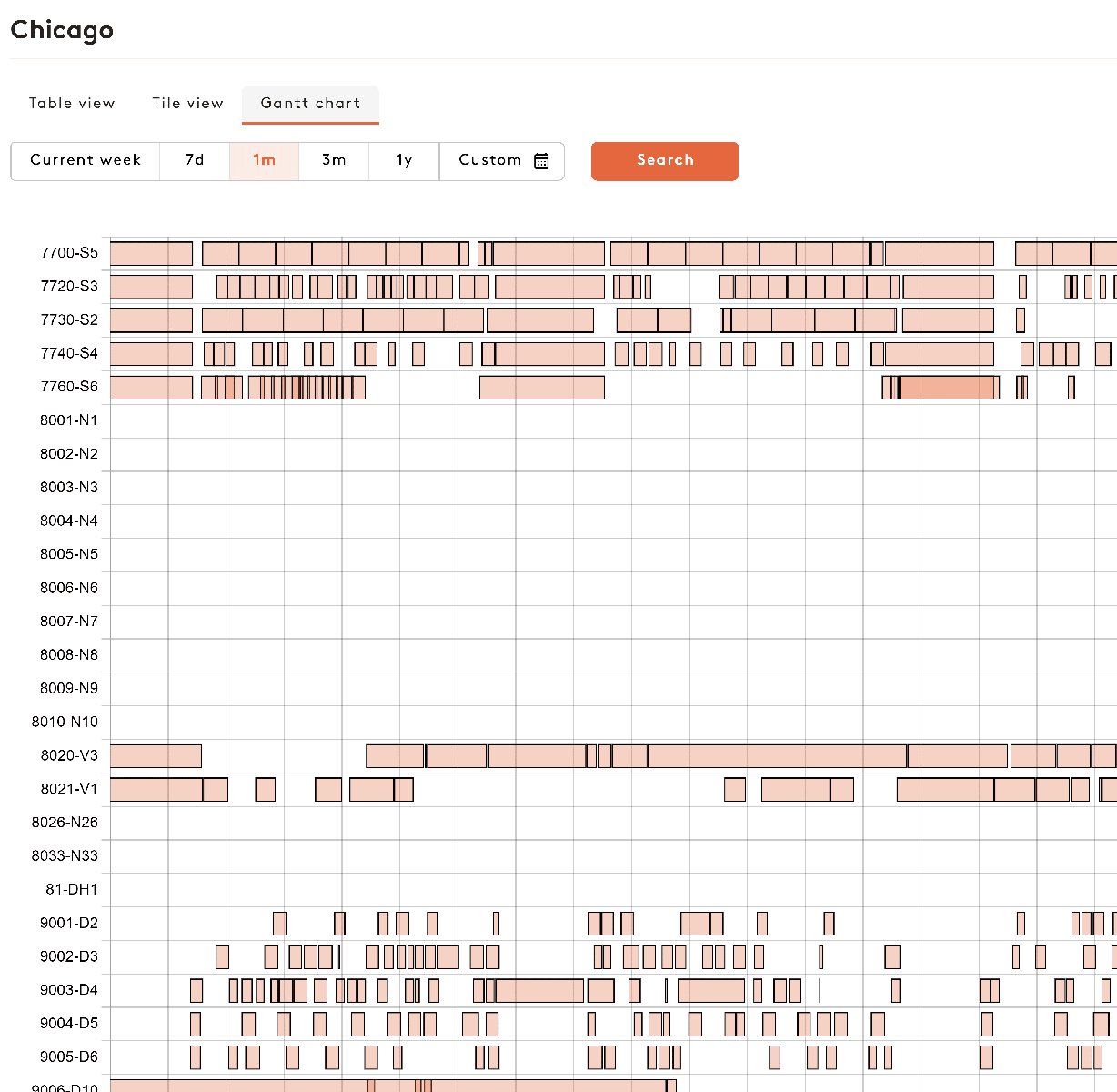

QMULUS Planner

Ease your planning using the scheduler and optimize throughput, including possibility of prioritization. Visualization in Gantt graphs provide the overall picture. The integrated order management allows to take over and manage shop orders.

- Orders/customers (Feature Coming Soon)

- Calendar

Qmulus add ons

QMULUS Automation

Bring lights out operation to your shop. The application for fully automated lines and to virtually automate a conventional production line. The integrated production planning optimizes your throughput according to your order books.

- Automated lines (Feature Coming Soon)

- Customers (Feature Coming Soon)

Qmulus Standalone

Simulators

Design and optimize recipes for carburizing processes and significantly reduce lead time for process development. (Feature Coming Soon)

Qmulus Standalone

Simulators

Simulate and model nitriding and nitrocarburizing processes in accordance with AMS 2759/10A and 2759/12A to achieve optimal results and reduce the lead time in process development. (Feature Coming Soon)

Qmulus Standalone

Simulators

Optimize your low-pressure carburizing processes with a simulation tool that provides both recipe accuracy and speed. (Feature Coming Soon)

Request a demo

A MORE POWERFUL, TECHNOLOGY-

DRIVEN IOT PLATFORM

Learn how to improve the sustainability and profitability of your heat treatment operations with QMULUS in this informative white paper.

![]() Identify and capitalize on new optimization

Identify and capitalize on new optimization

possibilities

![]() Maximize product quality while reducing

Maximize product quality while reducing

resource consumption

![]() Improve asset health, equipment availability,

Improve asset health, equipment availability,

and maintenance

![]() Improve profitability and long-term business

Improve profitability and long-term business

viability

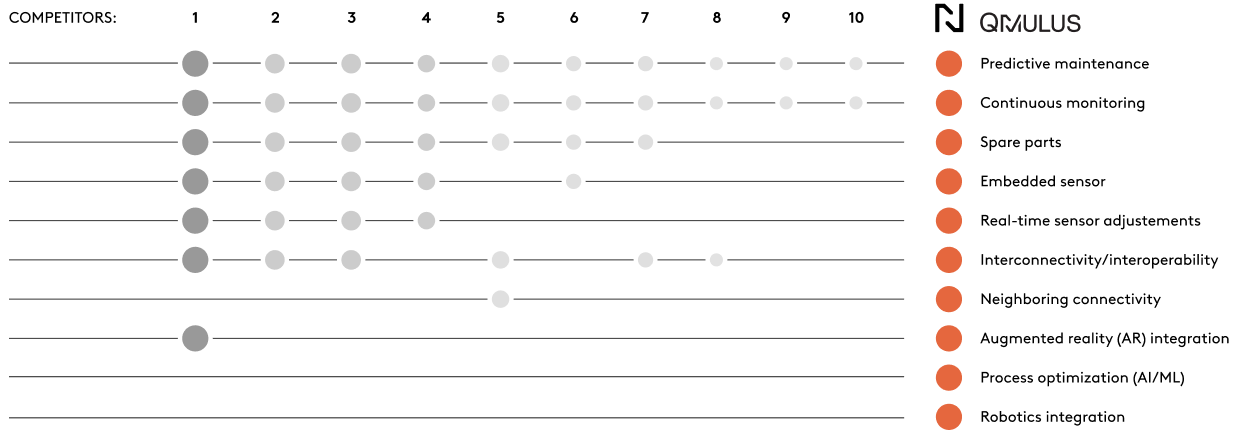

UNIQUE ON THE MARKET

QMULUS is at the forefront of the competitive landscape as the only company to provide

and offer a feature-rich IoT solution capable of connecting to a variety of systems.

RESOURCES

NEWS